FAUCET

OVERVIEW

Designing a faucet with a specific style and making a real size model by silicon molding and plastic casting.

SKILLS

3D printing

Spray painting

Molding & casting

SOFTWARE

Solidworks, Keyshot

Photoshop, Lightroom

DATE

Sept, 2012 - Dec, 2012

STYLE & TYPE

Traditional

Transitional

Contemporary

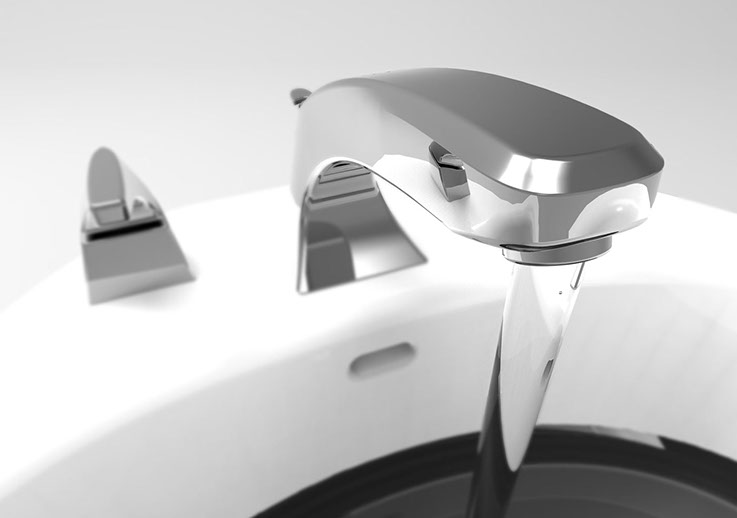

Transitional style

Widespread mount

Chrome finish

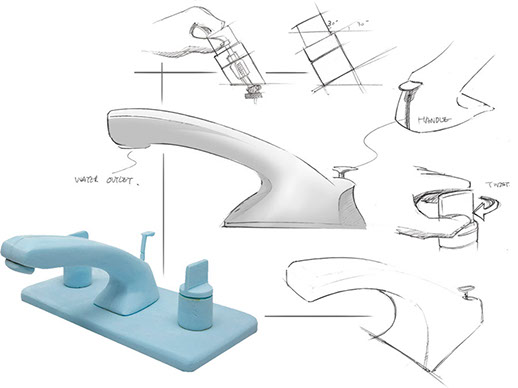

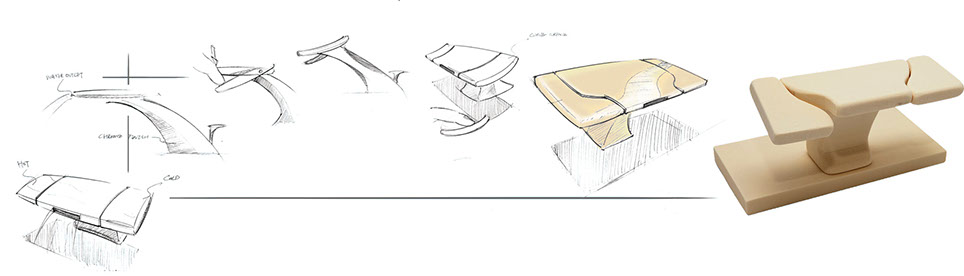

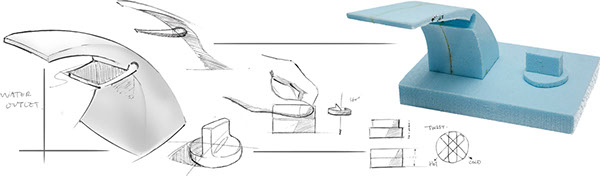

IDEATION & MOCK-UP

Focusing on usability, utility and desirability.

Final direction

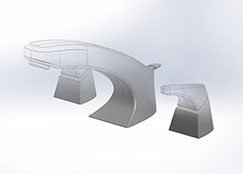

3D RENDERING

MODEL MAKING

3D printing & finishing

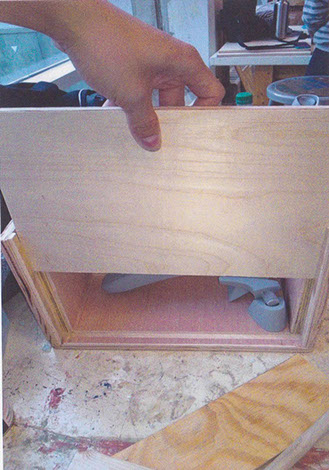

Building mold box

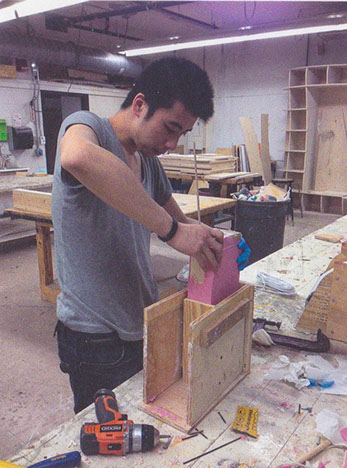

Parts fixation

Sanding and polishing the 3d printed parts for casting the glossy finish surface.

Building mold box based on parts dimensions with sliding walls for easy release.

Hanging and fixing molding parts inside the molding box.

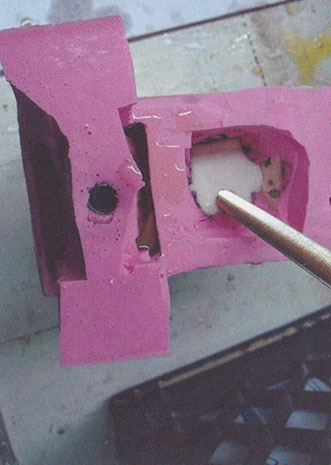

Making silicone mold

Demolding

Casting

Pouring mixed silicone from the edge of the mold box, until the parts were fully surrounded by liquid.

Waiting for 17-20 hours to cure the silicone mold. Taking the parts out of silicon mold.

Pouring liquid plastic into the silicone mold and waiting for 3-5 minutes until urethane plastic solidified. Taking out the casted parts for the final surface finishing.

FINISHED MODEL

© 2018 Will Wang Design